1. General description

The Machine is used for profile cutting the pipe terminal or pipe intersection part after the system calculation of the cutting path. There’s no need of the manual programming by the operator. The machine can work out and complete the cutting job After the operator input the intersected pipes’diameter,angle etc. the cutting surface is very good and no need for further treatment such as grinding or polish.

Configuration:

The machine is mainly consists of below units:

1. Machine base (by welded square tube structure)

2. Pipe Rotating mechanism (3-claw Chute and Rotating system)

3. Pipe (Workpiece) supporting Roller (The number depends on the pipe length)

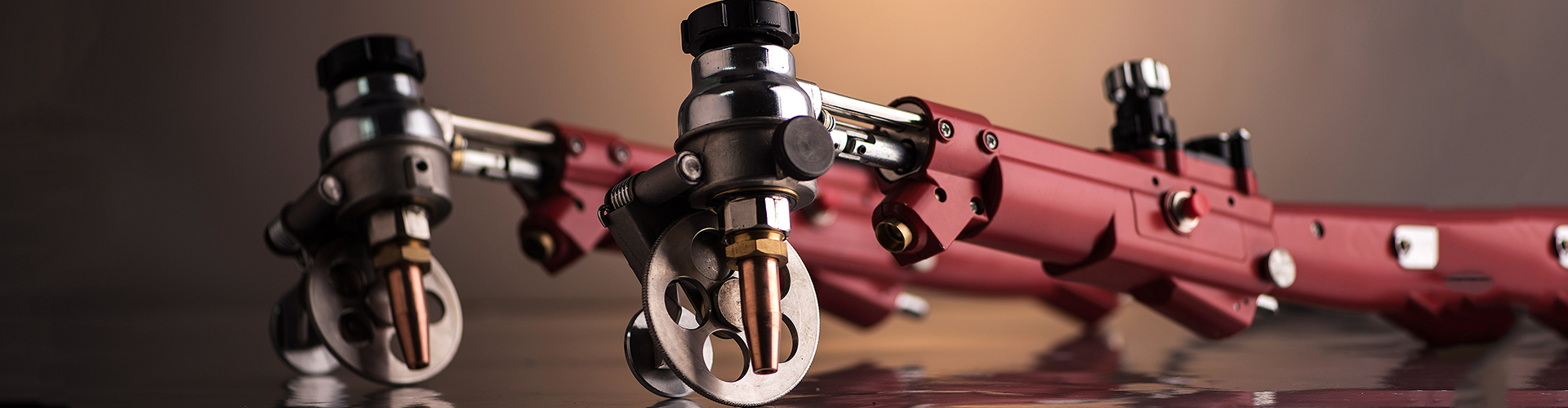

4. Torch drive unit

5. Torch lifting unit

6. Torchdeflectionunit

7. Travel Rails (Highprecision machined steel)

8. Electrical system

2. Main technical parameter

Workpiece size |

Pipe diameter [can be customerized] |

Φ=40~630mm |

|

Max.Valid workpiece length[can be customerized] |

12000mm |

||

Application and Workpiece material |

Is used for the pipe ends or pipe intersection cutting Workpiece material:Low Carbon Steel or mild steel by Oxy-fuel cutting CopperNickel,S.S by Plasma cutting |

||

Cutting data |

Cutting medium |

Oxyfuel/Plasma |

|

Plasma cutting wall thickness |

Quality Cutting 1~20mm Bevel Cutting 5-14mm |

||

Oxyfuel cutting wall thickness |

Straight Cutting 6~60mm Bevel Cutting 6-40mm |

||

Plasma Bevelling angle |

±45° |

||

Oxyfuel Bevelling angle |

±55°(Pierce) ±60°(Cutting from edge) |

||

Workpieceovality |

≤1% |

||

Cutting speed |

10~2000mm/min |

||

Moving speed |

10~6000 mm/min |

||

Cutting length accuracy |

± 1.5mm |

||

Cutting accuracy standard |

ISO9013-200、ISO8206-1991, JB/T10045.4-1999JB |

||

chuck |

type |

3-claw linked self-centered (Manually) |

|

Manual Chuck fastening device |

1set |

||

Support roller |

Number |

depends on the tube length, ie. 5 sets for 12m pipe |

|

Weight |

Workpiece |

5000Kg |

|

Color |

|

Blue |

|

3.Configuration in details:

SN |

Item |

Qty |

Remark |

1 |

Main Unit |

1set |

|

2 |

Machine base |

1set |

Welded steel structure (bysquare tube) |

3 |

Tube chuck |

1set |

Dia. 40-630(Bevel notrecommended for Tube Dia 40-80) |

4 |

Guide rail length |

㎜ |

It depends on the pipe length, normally the guidelength= pipe length+2m |

5 |

Motor |

4sets |

Panasonic or other contracted |

6 |

Driver |

4sets |

3P Servo driver |

7 |

Fine orbital reducer |

3sets |

Neugart |

8 |

CNC control system |

1set |

F430A by Shanghai Transport & Communication University |

9 |

Cross feed cable drive system |

1set |

Engineering tank chain (Al) |

10 |

Parallelogram holder |

1 |

To hold the torch |

11 |

Lengthway guide rail |

4 lines |

24kgs/meter |

12 |

Cutting station |

1set |

(for plasma cutting mode) |

13 |

CNC Torch |

1set |

Oxyfuel or Plasma) |

14 |

Solenoid valve |

3sets |

AIRTAC |

15 |

PLC |

1sets |

PLC |

16 |

Hose |

1set |

For Oxyfuel cutting mode |

17 |

Plasma Power |

1set |

OPTIONAL (Comes with the Plasma torch in general) The type depends on the cutting thickess, ie 200A for 20mm |

18 |

Contact+ nozzle |

10sets |

10sets(Contact tip+ Nozzle) |

19 |

Rotating Motor |

1set |

Servo motor 1500w |

21 |

Chuck |

1 |

40-320mm/400mm/630MM etc depends on the pipe Dia. |

22 |

Support roller |

|

It depends on the pipelength, ie.5sets for 12m pipe |

24 |

Software |

1 |

CAD |

25 |

Vent |

1 |

Reserve air extraction port (chuck) |

4. CUTTING ACCURACY

1 |

Speed Accuracy (%) |

≤±5% |

||

2 |

Height controller accuracy (mm) |

≤±1.0mm |

||

3 |

Lengthways line accuracy |

±0.5mm/10m |

||

4 |

Line repeat accuracy |

±0.5mm/10m |

||

5 |

General Accuracy (Refer to Right Diagram,1000╳1000 Square). Powder Marking speed 500-800mm/min |

|

||

6 |

Rail installation accuracy |

1).Primary rail side linear accuracy: 0.5mm/10000mm 2).Secondary rail side linear accuracy: 1mm/20000mm 3).depth of parallelism between Rail’s top surface and Horizontal: ±0.5mm/1000mm |

||

7 |

Intersection deviation |

1.0㎜ |

||

8 |

Linear accuracy |

±0.5㎜ |

||

9 |

Roundness |

1.0㎜ |

||

10 |

Diagonal difference |

1.0㎜ |

||

11 |

Repeatability |

1.0㎜ |

||

12 |

Powder Marking accuracy |

≤0.5mm |

||

13 |

Cutting surface quality (roughness)(if choose the materialδ=25) | Rz(um)=70+1.2a | ||