Positive

· Gantry structure adopted

· Widely used in shipbuilding,bridges constuction,steel fabrications,Petrol-chemical machiney and Vehicles production. etc

· Durable and stable with high rigidity structure, running smoothly with gapless gearing between rack and pinion which subject to precion machining.

· Continuous speed-adjustment, rack-pinion drive without backlash.

· High efficiency by simultaneously multi-torch cutting.

· Excellent cutting with less hot deformation.

· More choices/options available such as automatic ignition,automatic torch height lift,automatci piercing,traverse cutting,triple-torch assembly for x cutting, Plasma cutting.

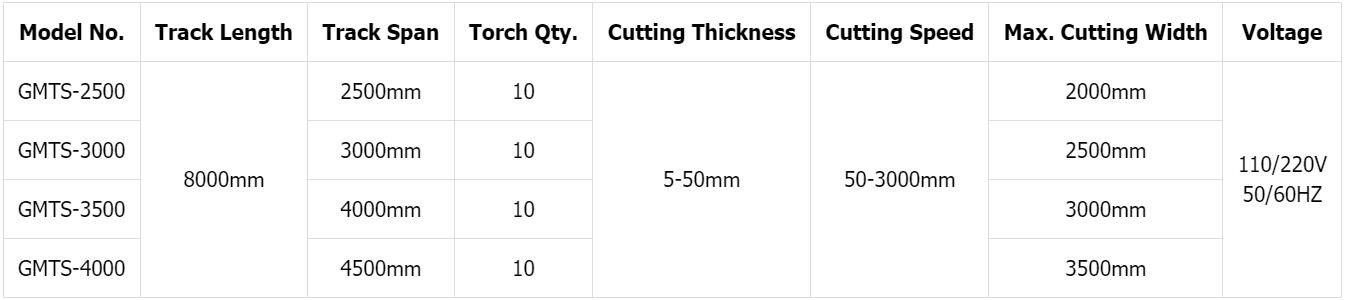

· Track Span:3000-6000

· Track length:8000mm ( Or customized, longer available upon customer's request)

· Minimum cutting width:80mm (60mm available)

· Cutting thickness: 6-100mm(depends on the torches numbers used simultaneously, Ie,6-200mm for the models with 4torches below and 0-80mm for the models with 5-10 torches)

· Max stripe speed

(Single side drive): 4000

(Synchronized dual side drive): 6000mm

* Track length and torch numbers can be supplied as per customer's request.

Negative

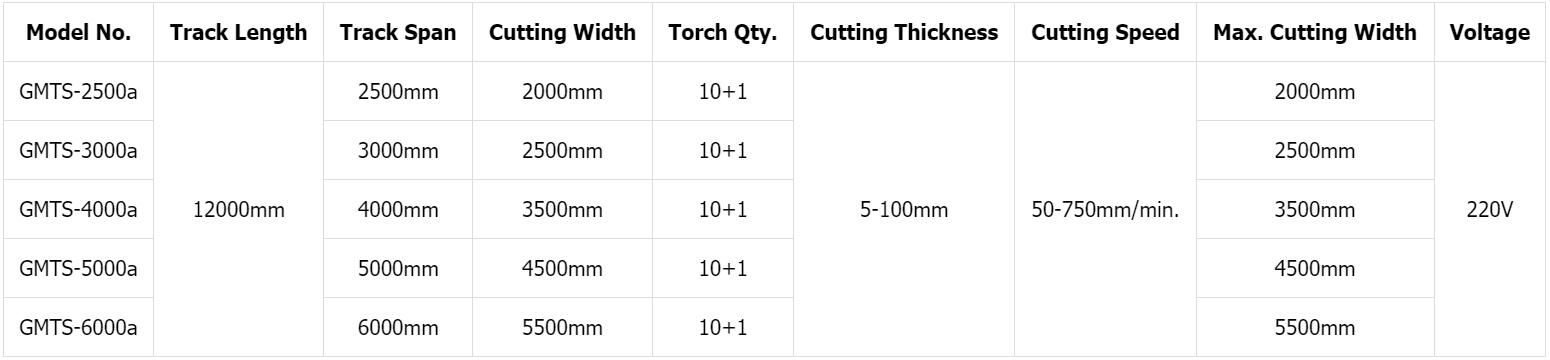

Standard Straight-line Multi-torch cutting machine

· Gantry structure adopted

· Widely used in shipbuilding,bridges constuction,steel fabrications,Petrol-chemical machiney and Vehicles production. etc

· Durable and stable with high rigidity structure, running smoothly with gapless gearing between rack and pinion which subject to precion machining.

· Continuous speed-adjustment, rack-pinion drive without backlash.

· High efficiency by simultaneously multi-torch cutting.

· Excellent cutting with less hot deformation.

· More choices/options available such as automatic ignition,automatic torch height lift,automatci piercing triple-torch assembly for x cutting, Plasma cutting.

· Track Span:3000-6000

· Track length:12000mm ( Or customized, longer available upon customer's request)

· Minimum cutting width:80mm (60mm available)

· Cutting thickness: 6-100mm(depends on the torches numbers used simultaneously, Ie,6-200mm for the models with 4torches below and 0-80mm for the models with 5-10 torches)

· Max stripe speed

(Single side drive):4000

(Synchronized dual side drive) 6000mm

* Track length and torch numbers can be supplied as per customer's request.