GW-11W Pipe Welding Carriage with Oscillator Weave Bird

GW-11W magnetic pipe welding carriage is a compact welding tractor which can travel around the pipe without any track or chains;

GW-11W magnetic pipe welding carriage is a compact welding tractor which can travel around the pipe without any track or chains; It can take a variety of welding paths under the control of the weaving control system. It can move forward / backward without any track ( can be changed to be with band track for S.S tube welding).Its installation and disassembly is very convenient and widely used in ship buildings, roads and bridges engineering projects, locomotives, steel construction , petrochemical and other mechanical industries.

Features:

● Reduce labor intensity, improve the working environment.

● Improve work efficiency; it is 1.5 times of that manual welding.

● Avoid poor quality welds caused by human factors. the general defect rate of manual operation is about 20%, while using this automatic welding carriage it can minimized to be almost zero.

● High degree of automation ensures the stability of the welding quality.

● With weaving function and a lot of welding path choices to achieve the best effect:

● Even unskilled workers can quickly learn to operate it..

Traveling speed Drive type Torch adjustment Weaving Speed Clutch Weaving range Weight Machine szie

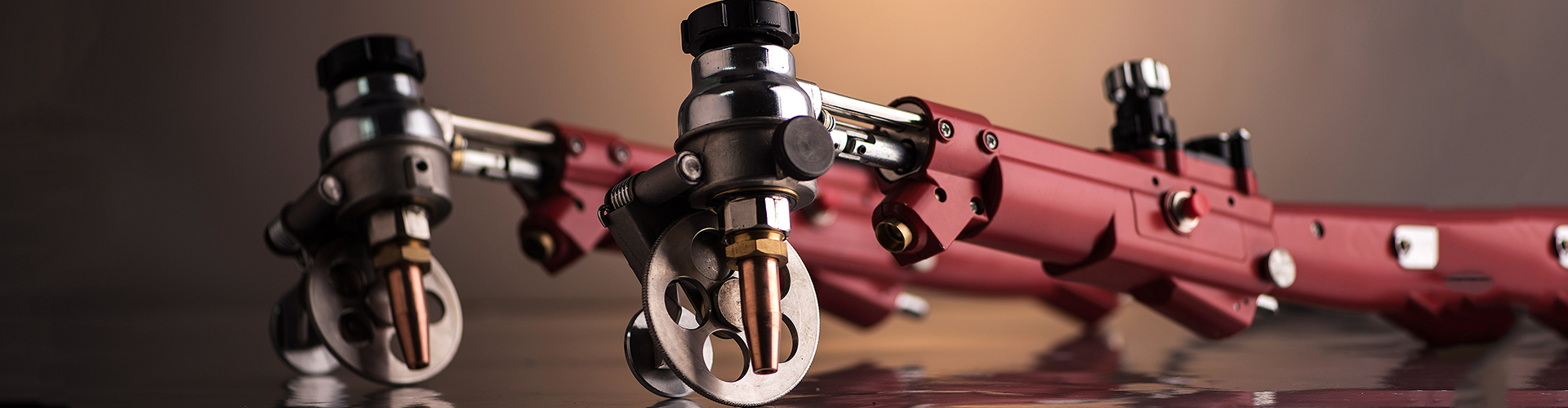

Oscillator

GW-11W

1:Model GW-11W-N For MIG Application

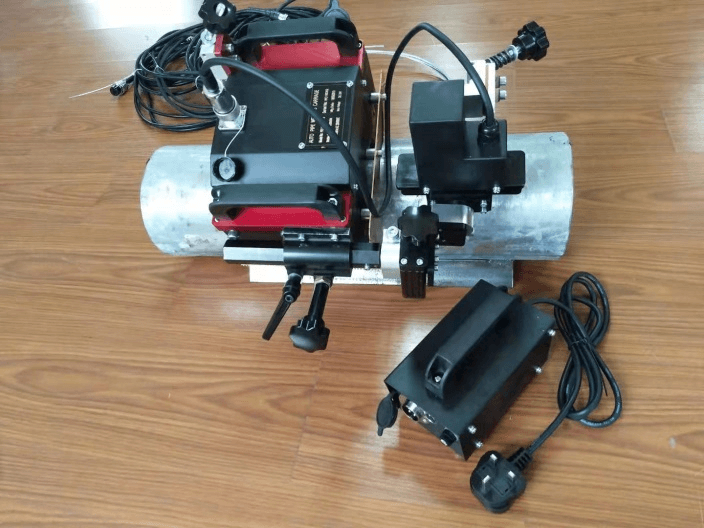

Main unit (Torch optional)

Whole set upon supply

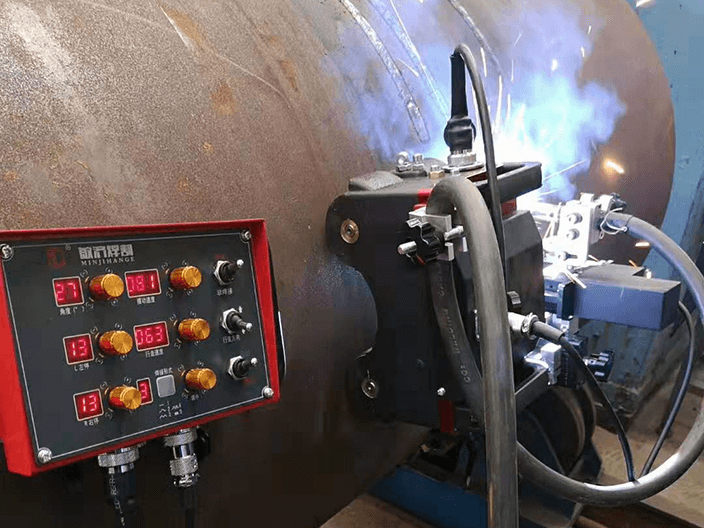

Working on site with remote control unit

2.MODEL GW-11W-PLUS for both MIG and TIG Application

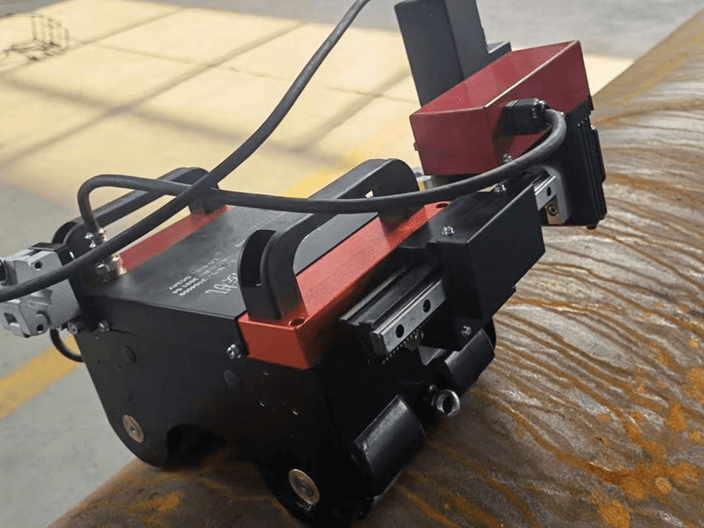

SIDE A VIEW

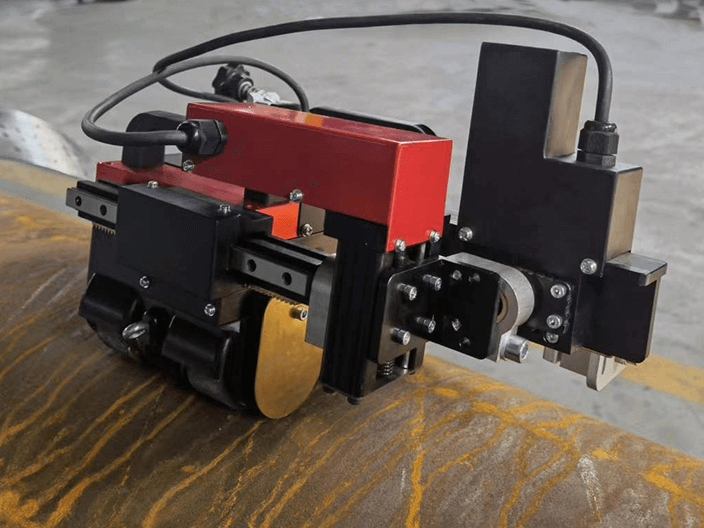

SIDE B VIEW

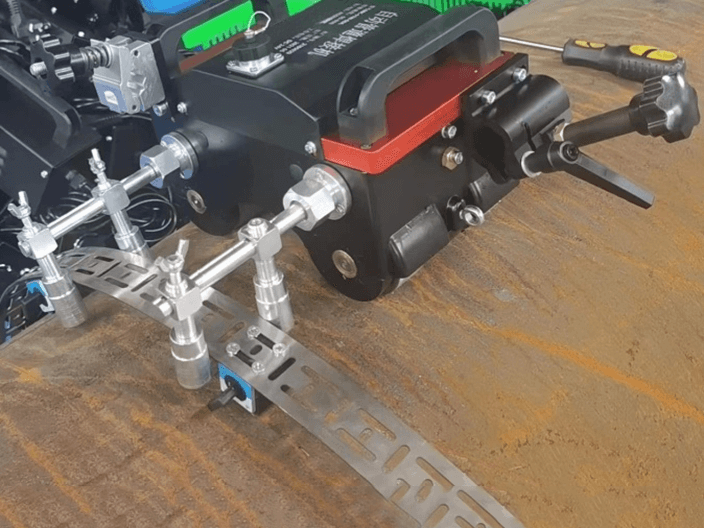

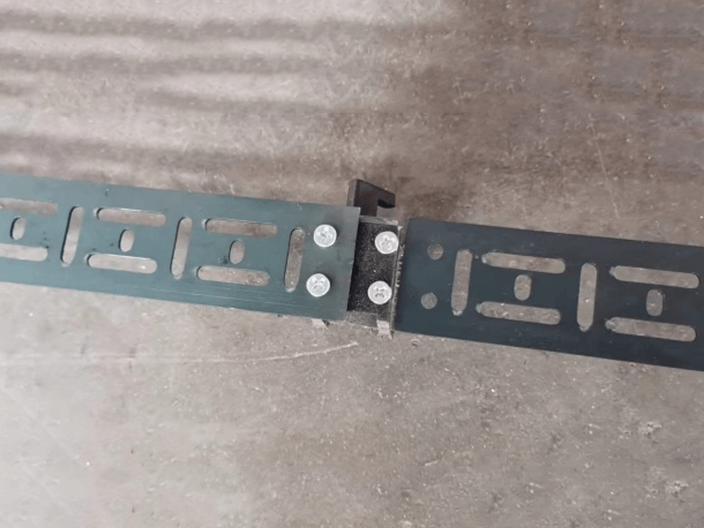

3.RAIL set for GW-11W(OPTIONAL)

Guide Rail set installed

Guide Rails connection

4. GW-11W-NF

This is for non-ferrous Tig/ Mig welding application (Riding on the guide belt)

Outline of machine of standard type

5. Name and function of each section:

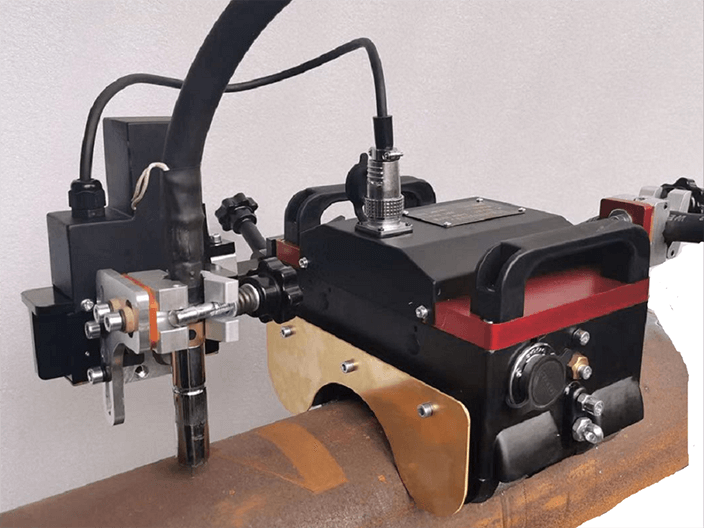

The Carriage is made up of Main Body, Control Box, Torch Holder, Guide Roller.

1)Main Body: It’s the drive unit including motor, reduction box, drive gear unit.

2)Control Box: Setting or adjusting all movements of the carriage. Details refer to the “Control Panel” here after.

3)Cross-feed Unit: Adjust the welding torch horizontally instead of moving the carriage body frequently 。

4)Fine adjust block: Move slightly the position of the welding torch during operation.

5)Oscillator: Control the welding path。

6)Torch holder: used to hold the torch. Be aware that don’t hold the torch on the Conductive part. Otherwise it might cause short-circuit or shock.

7)Power Socket: input from the outer power, it also connects with the ground wire.

8)Handle: Used to Carry the machine。

9)Torch fine adjustment unit: Help to align the torch to the welding target exactly

10)Cable Support (hanger): Hold the cables to reduce the load on the oscillator.

11)Welding torch: Can be straight or swan type,to be prepared by the users otherwise contracted.