I. Summary and features:

1. Summary:

THCD-14 automatic welding machine adopts gear and chain transmission mode, and its structure is compact, light and reliable.

The whole machine is powered by battery, which is safe and reliable; The magnetic adsorption device of car body has clutch function, which is convenient for operators to work on site.

2. Features:

1) The battery is used for power supply, which eliminates high-voltage wiring, improves the safety performance of the car and simplifies the wiring of the car.

2) Small size, low center of gravity, light and easy to carry.

3) The high-strength magnetic magnet obviously enhances the reliability of copying operation, increases the traction force and ensures the smooth operation.

4) Copying walking is stable, operation reliability is high, and multiple devices can be operated at the same time.

5) The guide device is a screw locking type, and the height of the guide wheel can meet any adjustment of 0-60mm.

6) Digital display combined with speed feedback technology is adopted for walking speed, which has high speed control accuracy.

7) Reduce labor intensity and improve working environment; Improve work efficiency, which is 1.5 times that of manual welding.

8) High degree of automation to ensure the stability of welding quality.

9) Simple operation, workers can quickly grasp the essentials of operation.

II. The applicable workpiece and shape:

Our company's THCD-14 automatic welding machine has powerful functions and wide applications, and is suitable for fillet welding, upturned fillet welding and flip-chip welding of transport vehicle floor of steel plates and duplex stainless steel materials in industries such as ships, bridges, locomotives, steel structures, petrochemical industries, etc. Such as: reinforcing rib plate, rib plate, corner welding of crossing parts, etc.

III. Specifications and Technical Parameters

Project |

Technical specifications |

Model |

THCD-14 |

Machine weight |

8.3Kg |

input voltage |

24V battery supply (4AH) |

Driving method |

Four-wheel drive |

adsorption capacity |

20Kg |

operating speed |

65 ~800(mm/min) |

Tracking mode |

Type guide wheel |

Guide wheel height |

0-60mm |

Welding torch adjustment range |

Horizontal angle: 40 ~ 55 |

Up and down movement: about 40mm movement: 40mm |

|

Manual fine adjustment: 8 |

|

welding gun |

Curved or straight gun |

Unwelded length |

The front end: 120mm and the rear end: 125mm |

Automatic stop function (optional function) |

Front rear two-end limit switch |

Dimensions (length× width× height) |

250×230×270mm |

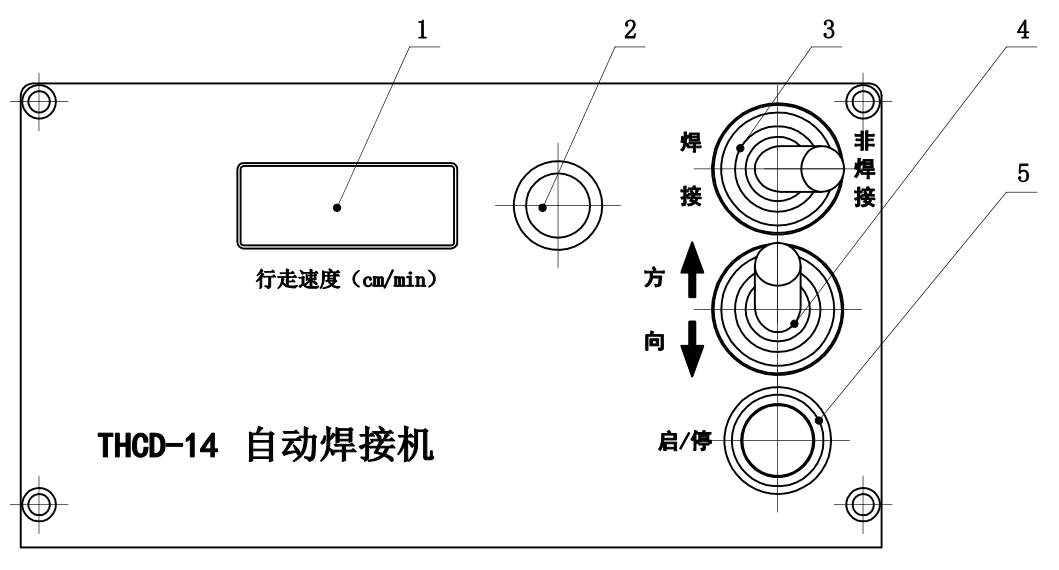

IV. Control structure of automatic welding machine panel

No. |

Name |

Function |

1 |

Travelling speed Display digital tube |

The display format is XX.X, which is used to actually display the magnitude of the travelling speed. |

2 |

Travelling speed Adjustment potentiometer |

Rotate the potentiometer rotary axis to adjust the travel speed value, clockwise rotation increases the value, counterclockwise rotation decreases the value. |

3 |

Welding/non-welding control switch |

Used to control the welding state, switch to "welding", then welding and trolley synchronous, start the trolley welding power synchronous action (arc start delay time is still valid, at the same time, need to trolley welding gun port and power wire feeder connected correctly). |

4 |

Travelling direction control switch |

It is used to switch the travelling direction of the trolley, if the switch is pushed to the left travelling trolley, it will travel to the left, and similarly if the switch is pushed to the right travelling trolley, it will travel to the right. |

5 |

Start-stop switch |

It is used to switch the start-stop state of the trolley, every time the switch is pushed, the trolley will switch between start-stop state once. |

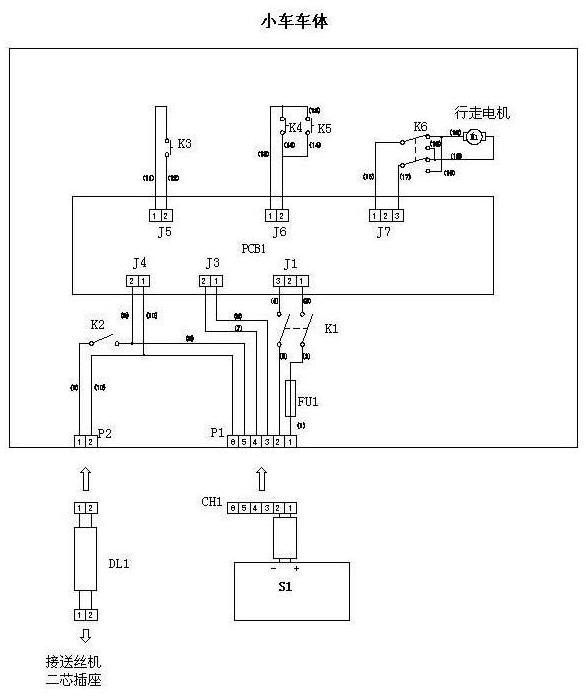

V. Electrical schematic diagram of automatic welding machine