I. Summary and features:

1. Summary:

1.1、THCD-9 is a walking welding equipment driven by gears and chains, with built-in high-performance permanent magnets. The welding gun clamping mechanism can exchange clamping gas shielded welding guns and argon arc welding guns, which are used for butt welding of pipelines, fillet welding of pipelines and flanges or elbows, etc. The clamping argon arc welding guns can be used as argon arc welding machines.

1.2、The whole machine is compact, light and stable in structure; The battery is used for power supply, which is especially suitable for outdoor and welding occasions where it is not convenient to supply trolley power, so as to prevent the potential safety hazard caused by electric shock caused by the damage of power cable on site.

1.3、The clamping mechanism of welding gun has swinging function, which is suitable for welding wide and thick welds. The positioning accuracy is assured andthespeed of crawling can be kepteven andconstant in both up-slope or down-slope welding, and even operators without professional skills can get good welding results.

2. Features:

1) The DC24V lithium battery is used for power supply, which eliminates the high-voltage power supply of the car body and improves the safety performance of the car.

2) Digital display of digital tube is convenient for adjusting various parameters, small in size, low in center of gravity and easy to carry.

3) The walking speed, swing speed, swing angle, left and right residence time, etc. are precisely controlled by program.

4) The swinging device is controlled by the program, and the swinging device has the functions of left stop and right stop, so as to prevent the phenomenon of insufficient molten pool during swinging welding; At the same time, the weld center can be adjusted during welding to prevent partial welding.

5) The swing function always starts from the center and automatically returns to the center, which is convenient for the second start of welding adjustment.

II. Scope of application:

2.1. Applicable materials: carbon steel, stainless steel, alloy steel and low-temperature steel (materials that cannot be magnetically adsorbed should be equipped with trolley rails).

2.2. Applicable welds: pipe-pipe girth welding, pipe-elbow, pipe-flange, horizontal welding and vertical welding of tank body,Horizontal welding of pipe piles, etc.,

2.3. Applicable pipe diameter: cylindrical pipe ≧ 140mm, inner diameter ≧ 450mm, applicable wall thickness 3-100mm,

2.4. The walking width of the welding trolley should be greater than 300mm, and the gap between the weld base materials should be consistent, otherwise the welding effect will be affected;

2.5. The workpiece (or fixed guide rail) should be made of magnetic conductive material. If there is no magnetic conductivity, the trolley magnet can't be adsorbed on the workpiece, which will cause the trolley to run unsteadily or even fall and be damaged (materials that can't be magnetically adsorbed should be equipped with trolley rails).

III、Specifications and technical parameters:

Serial number |

Item |

Parameter internal capacity |

|

1 |

Applicable workpiece |

Iron workpiece, fillet weld, butt weld |

|

2 |

type of drive |

Four-wheel drive (rubber wheel) |

|

3 |

Adsorption force (steel plate test) |

≥30KG |

|

4 |

Vertical walking speed |

35 — 900 (mm/min) |

|

5 |

Swing speed |

0-40 cycles/min |

|

6 |

Left/right dwell time |

0—2.5S |

|

7 |

Swing angle |

0—±8° |

|

8 |

Meet the arc outside diameter. |

R≧170mm |

|

9 |

Meet the inner diameter of arc. |

R≥450mm |

|

10 |

welding gun regulate range |

crosswise |

40mm |

be on the perpendicular |

40mm |

||

Rotate around x axis of welding gun. |

±45° |

||

The welding gun rotates around the Y axis. |

±30° |

||

11 |

Material |

aluminium alloy |

|

12 |

Input power supply |

24V-4AH lithium battery |

|

The working time of one charge shall not be less than 10 hours. |

|||

13 |

Trolley size |

Length× width× height: 200×285×242 |

|

14 |

Weight |

12kg |

|

IV. Main components of the product:

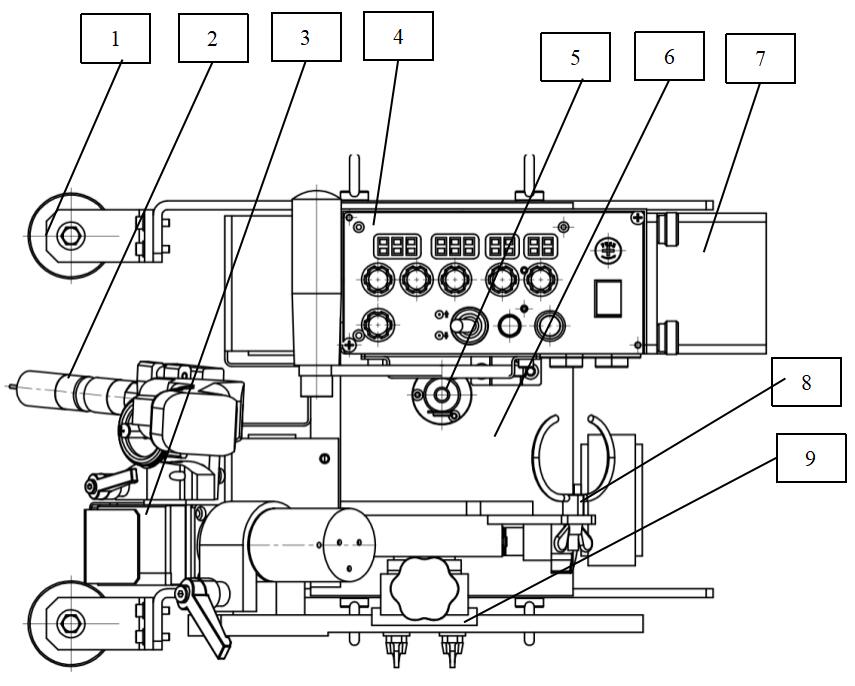

4.1: Schematic diagram of THCD-9 pipeline all-position machine (the picture is for reference only, subject to the actual product)

4.2 Structure name:

Number |

Naming |

Gongneng |

one |

Left and right guide wheel parts |

The guide wheel should be close to the vertical plate, fixed and adjusted by screws, and the walking direction of the guide wheel is 5-10mm shorter than that of the rear push, thus playing the role of profiling guide. |

two |

Welding gun clamping part |

Used for centering clamping welding gun and copying welding gun. |

three |

oscillator |

Drive the welding gun to swing in the direction of welding seam, and adjust the swing angle through the electric knob to meet the needs of wide seam width. |

four |

control box |

Used for the electric operation of the trolley. See Article 4.1 Control Box for specific operation contents. |

five |

Magnetic control handle assembly |

The attraction of the magnet is controlled by this handle, with upward separation and downward engagement. (Note: If the trolley is close to the steel plate, the trolley may be automatically adsorbed on the steel plate. Be careful not to insert hands and clothes into it) |

six |

Car body parts |

The main body of the trolley and the traveling device. |

seven |

24V-4AH battery pack |

The battery pow supply device provides pow for that running of the trolley and reduces the dependence on external power supply. |

eight |

Welding torch cable clamping assembly |

Used for clamping welding torch cable |

nine |

Cross adjusting mechanism |

Used to adjust the working position of welding gun. |

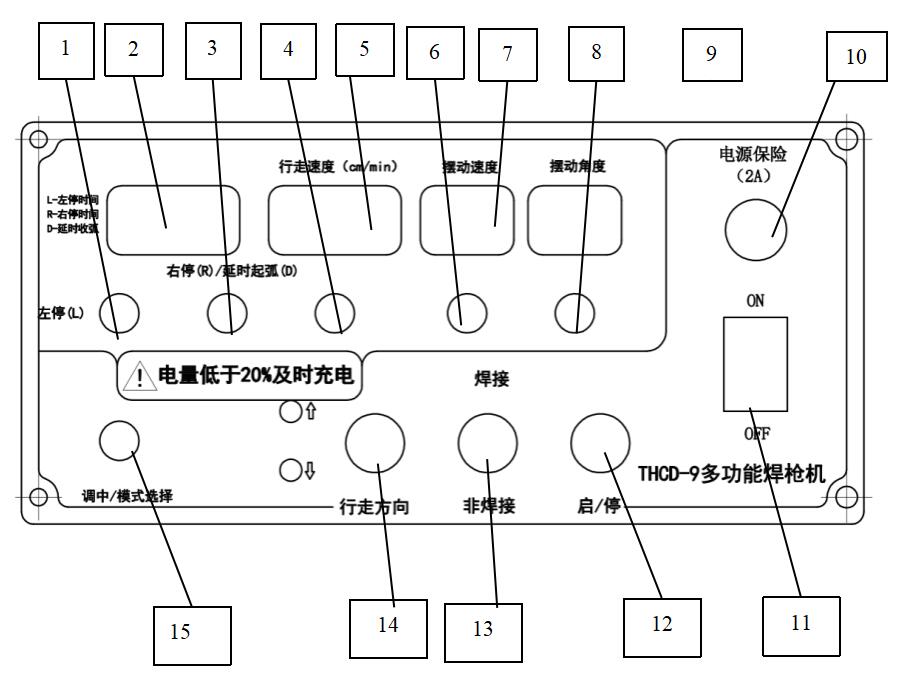

V. The control panel operation instructions:

Ⅵ.Control box function key name function:

Serial number |

Naming |

Function |

one |

Welding process time Adjusting potentiometer |

The potentiometer has a pressing function, which is used to display the switch of parameter marks; Rotate the potentiometer shaft to adjust the time parameter corresponding to the displayed parameter mark, and the clockwise parameter increases and the counterclockwise parameter decreases; |

two |

Display nixie tube |

In the normal mode, the welding process time is displayed in the format of X Y.Z, where: X is the display mark. L-dwell time of swinging left limit position; R-dwell time of swinging right pole position; D—welding arc closing time. Y.Z is the specific time value corresponding to the above mark, and the display range is 0–2.5. The format is X Y.Y |

three |

Speed regulating potentiometer |

Rotate the potentiometer shaft to adjust the walking speed value. |

four |

Walking speed Display nixie tube |

The format is XX.X, which is used to actually display the walking speed; |

five |

Swing speed Adjusting potentiometer |

Rotate the potentiometer shaft to adjust the swing speed. The clockwise value increases and the counterclockwise value decreases. |

six |

Swing speed Display nixie tube |

The display format is XX, which is used to proportionally display the swinging speed of the swinger; |

seven |

Swing angle Adjusting potentiometer |

Rotate the potentiometer shaft to adjust the swing angle, increasing clockwise and decreasing counterclockwise; |

eight |

Swing angle Display nixie tube |

The format is XX, which is used to display the swing angle proportionally. |

nine |

Trolley power switch |

Control the on-off of the trolley power supply; |

ten |

Power fuse |

Carry out overcurrent protection on the power supply circuit of the trolley, and the fusing current is 2A;

|

eleven |

Start-stop switch |

Used to switch the start-stop state of the car. Every time the switch is pressed, the car switches between the start-stop states once; |

twelve |

Welding/non-welding control switch |

It is used to control the welding state. When the switch is set to "Welding", the welding will be synchronized with the trolley, and the welding power supply will act synchronously when the trolley is started (the arc starting delay time is still valid, and the welding gun port of the trolley needs to be correctly connected with the power feeder). |

thireen |

Travel direction control switch |

It is used to switch the walking direction of the trolley. Every time the trolley is pressed, the walking direction of the trolley is switched between the left and right directions, and at the same time, the walking direction light completes the corresponding display switching. |

fourteen |

Walking direction indicator |

Show the walking direction of the car, the car goes right when the lights are on, and the car goes left when the lights are off; |

fifteen |

Medium potentiometer |

Used to adjust the swing center position of the swinger, clockwise to the right and counterclockwise to the left; |

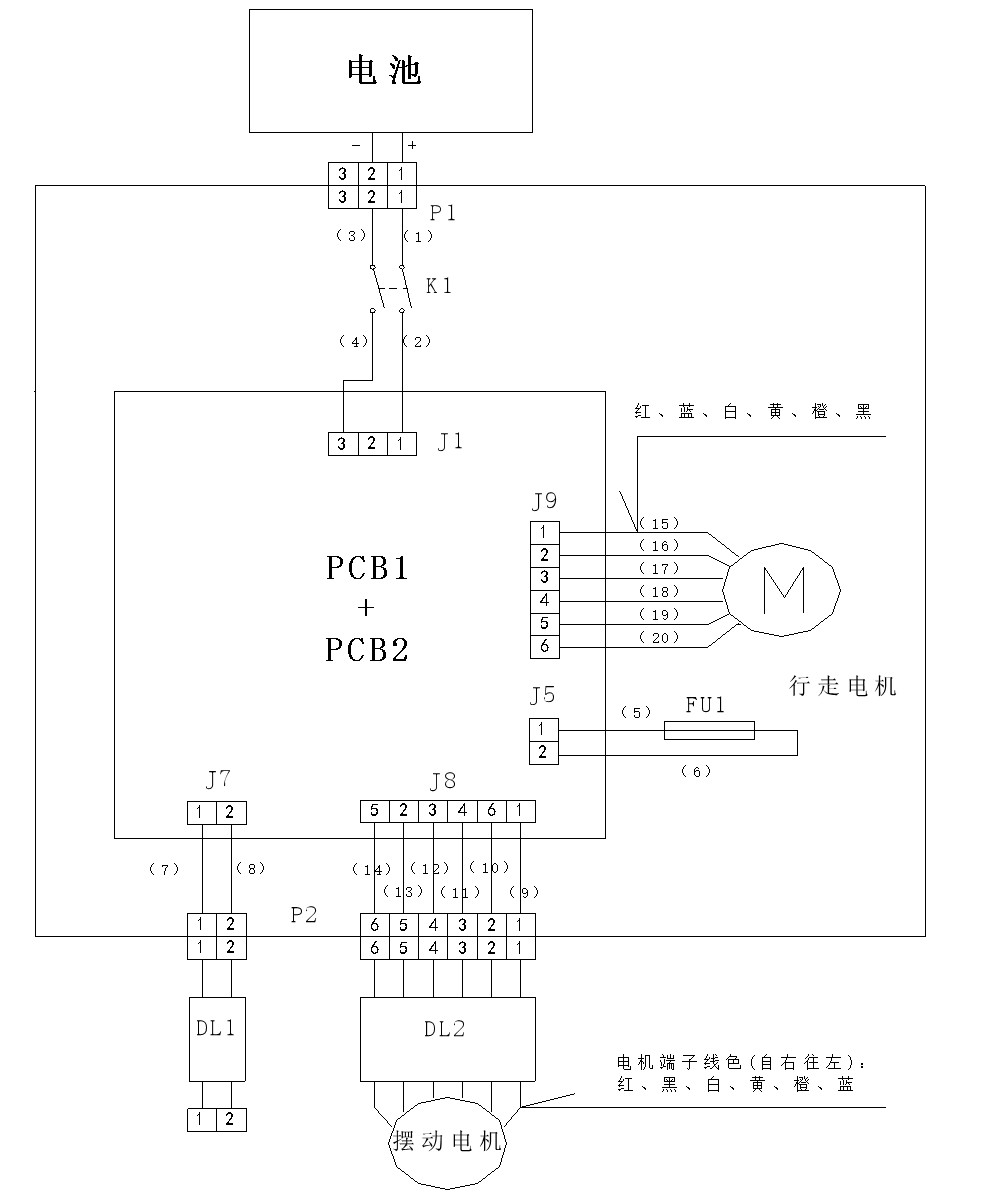

VII. Electrical Principle: