1. Structures and Functions

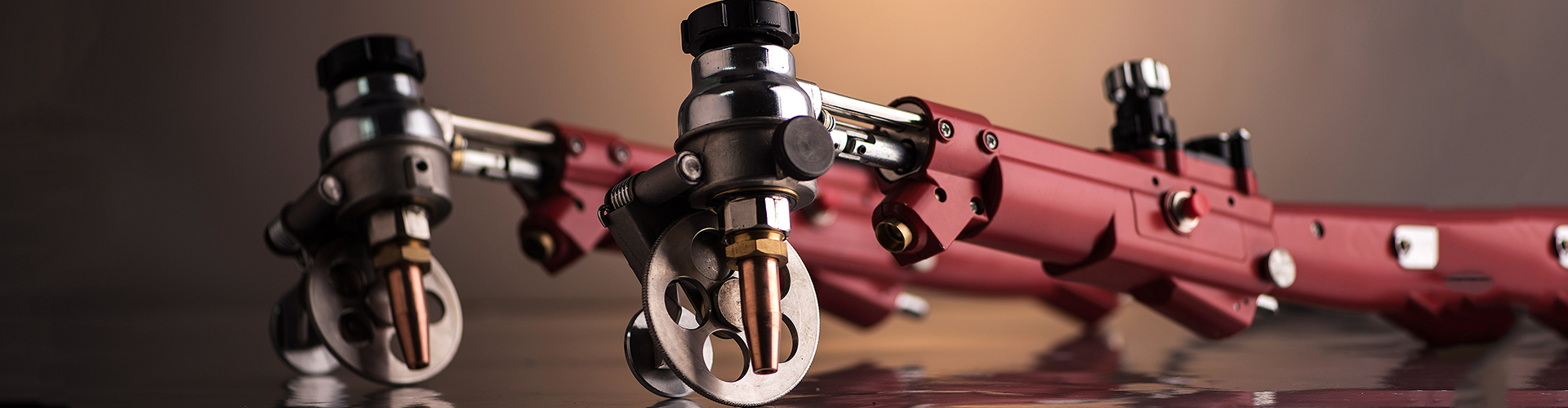

GW-8SS-II is made up of carriage body, guide wheel, to Torch, X-Y slide unit, weaving

Unit, control box etc., among which the carriage base is the basis to bear other fittings.

carriage body:It is the frame of machine and carrier of others.

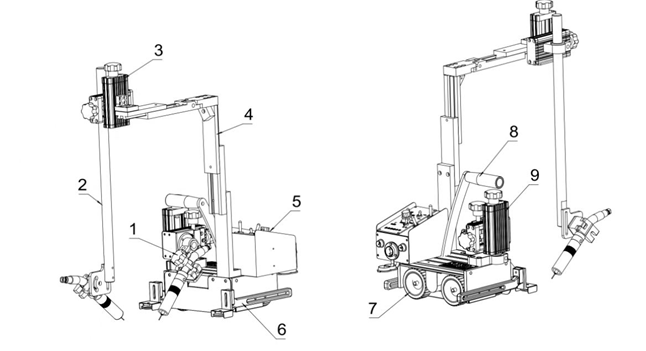

1 |

Torch Holder unit |

6 |

Guide wheel bar |

2 |

Holder Connection Bar |

7 |

Wheel |

3 |

X-Y Slie Seat for Torch 2 |

8 |

Carry handle unit (or Magnetic control clutch handle) |

4 |

X-Y Slide unit |

||

5 |

Control pnel |

9 |

X-Y Slide seat for Torch 1 |

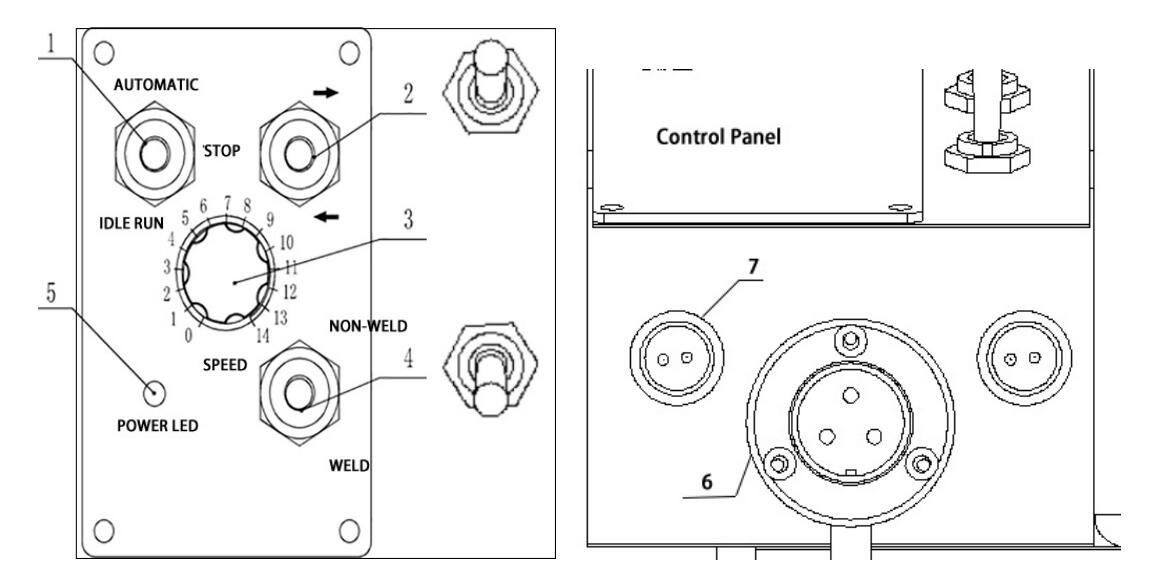

2. The control panellayout

1. Set the switch for diffident operation mode: Idle run, Automatic or stop.

2. Choose the switch for movement directions such as forward and backward (Arrow).

3. Set the speed by turning the speed adjustment knob.

4. Choose the switch for welding machine’s state: weld and non-weld.

5. POWER LED indicates the power is on or off.

6. Three-core socket: connected to power supply (DC24V).

7. Two-core socket: connected to the controlling switch of the Welding Torch.

1. size |

W300mm×L(510-610)mm×H(410-550)mm |

|

2. Main unit Weight |

11.8Kg |

|

3. Power |

AC220V / DC24V |

|

4. power |

22W |

|

5.adsorbability |

10~25Kg |

|

6. walking speed |

50~900mm/min |

|

7. Range of adjusting welding torch |

Up/ down |

50mm |

Left/ right |

50mm |

|

Range of working angle |

±45° |

|

Range of Proceeding angle |

10° |

|

Range of Rotating angle |

360° |

|

4. LAYOUT SIZE