I. Summary and features:

1. Summary:

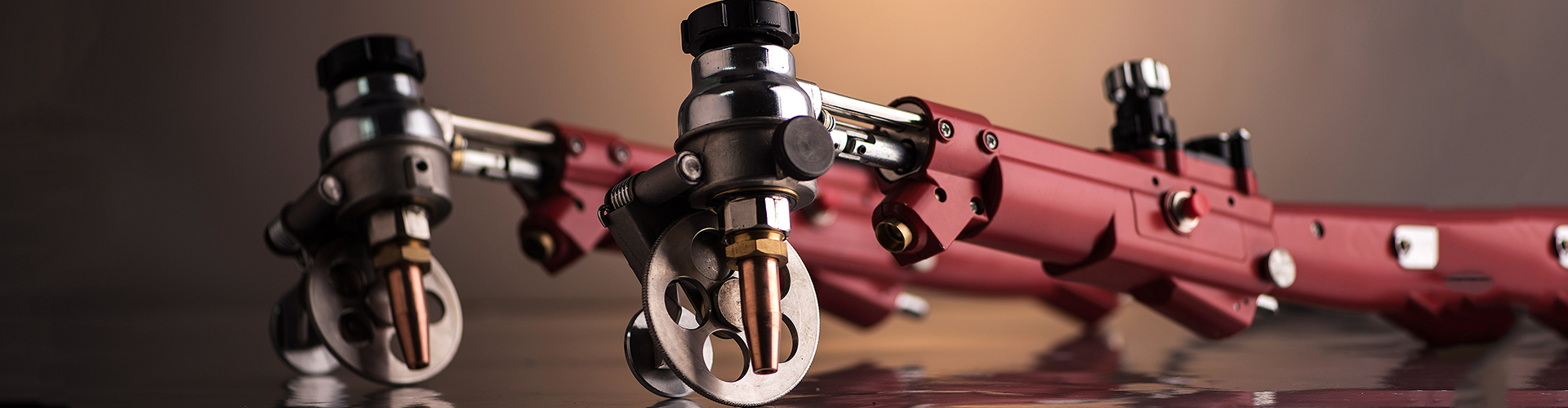

1.1、THCD-6 straddle-type corner welder is clamped by walking rollers on both sides, and the trolley is clamped and installed on the welding rib plate by cam locking. Brushless motor drive, gear and chain drive are adopted for two-wheel drive walking. The whole machine is compact, light and stable in structure, especially suitable for the maintenance hatch, flange sealing edge, fence and similar structural parts with T-row width, narrow space and steel structure in sections of ships, and can trace the welding seam to complete welding.

1.2、The battery is used for power supply, which is especially suitable for outdoor and welding occasions where it is inconvenient to provide trolley power supply, so as to prevent potential safety hazards caused by cable damage on site. The trolley runs stably and reliably, and even operators without professional skills can get good welding results.

2. Features:

2.1) The DC24V lithium battery is used for power supply, which eliminates the high-voltage power supply of the car body and improves the safety performance of the car;

2.2) The ribbed plate is mounted and walked in a straddle type, and the clutch device is mounted on the car body, so that the car body can be moved manually and quickly. Small size,Low center of gravity, easy to carry;

2.3) The elastic profiling presses the wall side to walk, and the pressing force can be adjusted according to the wall thickness and running stability to meet the welding requirements of non-magnetic materials;

2.4) Wide application range, meet the thickness of 5-50mm, height of 50-300 mm steel plate clamping, walking minimum inner arc.R≥350mm, minimum outer arc R ≧ 170mm;

2.5) Walking motor is driven by brushless motor, and its service life is 3-5 times of that of brushed motor;

2.6) Digital display combined with speed feedback technology is adopted for walking speed, which has high speed control accuracy;

2.7) Reduce labor intensity and improve the working environment; Improve work efficiency, which is more than 2 times that of manual welding;

2.8) It can effectively avoid the poor weld quality caused by human factors, and the defective rate of general manual operation is about 20%.

Right, and the use of automatic welding trolley does not produce welding defect rate, so its comprehensive benefit is nearly 200% higher than that of manual welding;

II. Scope of application:

2.1 Widely used, suitable for the workpiece thickness of 5-40mm, height of 50mm-300mm, ships, bridges, locomotives,Steel structure, petrochemical industry, etc. strengthen the fillet welding of stiffener, and the minimum inner arc r of stiffener clamping and walking is ≥ 350mm.The minimum outer arc R≧170mm.

2.2. It can meet the fillet welding of non-magnetic materials such as steel plate and duplex stainless steel.

2.3 Applicable welding materials: applicable to common welding wires and flux-cored wires with φ Φ1.6mm or less.

III. Specifications and technical parameters:

Serial Number |

Item |

Parameter internal capacity |

|

1 |

Applicable workpiece |

Iron workpiece, fillet weld, butt weld |

|

2 |

Walking mode |

Tracking-guide wheel profiling |

|

3 |

Vertical walking speed |

65 — 930 (cm/min) |

|

4 |

Reinforcement height |

50-300mm |

|

5 |

Meet the arc outside diameter. |

R≧170mm |

|

6 |

Meet the inner diameter of arc. |

R≥350mm |

|

7 |

welding gun regulate range |

crosswise |

40mm |

be on the perpendicular |

40mm |

||

Rotate around x axis of welding gun. |

±45° |

||

The welding gun rotates around the Y axis. |

±30° |

||

8 |

Input power supply |

24V-3AH lithium battery |

|

The working time of one charge shall not be less than 10 hours. |

|||

9 |

Trolley size |

Length× width× height: 200×395×242 |

|

10 |

Weight |

9kg |

|

IV. Main components of the product:

1、Schematic diagram of THCD-6 straddle angle welder (the picture is for reference only, and the product in kind shall prevail)

Number |

Naming |

Gongneng |

one |

Adjusting mechanism |

Clamp the rollers on both sides, and the guide wheel will follow the contour. |

Two |

Height adjusting mechanism |

Meet the height adjustment of certain circle and arc workpiece. |

three |

Car body parts |

The main body of the trolley and the traveling device. |

four |

Welding gun clamping part |

Used for centering clamping welding gun and copying welding gun. |

five |

Guide wheel assembly |

Used to connect the car body with the track assembly and play a guiding role. |

six |

Position adjusting mechanism |

Used to adjust the working position of welding gun. |

seven |

control box |

Used for the electric operation of the trolley. See Article 4.1 Control Box for specific operation contents. |

IIII. Operating instructions of control panel:

Number |

Naming |

Gongneng |

one |

Adjusting mechanism |

Clamp the rollers on both sides, and the guide wheel will follow the contour. |

Two |

Height adjusting mechanism |

Meet the height adjustment of certain circle and arc workpiece. |

three |

Car body parts |

The main body of the trolley and the traveling device. |

four |

Welding gun clamping part |

Used for centering clamping welding gun and copying welding gun. |

five |

Guide wheel assembly |

Used to connect the car body with the track assembly and play a guiding role. |

six |

Position adjusting mechanism |

Used to adjust the working position of welding gun. |

seven |

control box |

Used for the electric operation of the trolley. See Article 4.1 Control Box for specific operation contents. |

V. Electrical schematic diagram of automatic welding machine