I. Summary and features:

1. Summary:

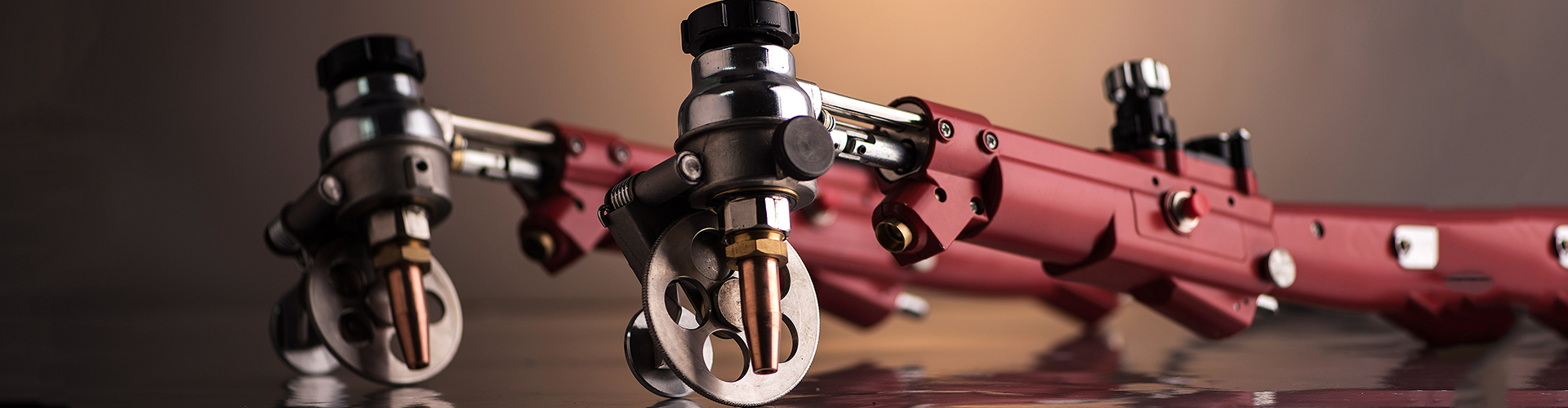

THCD-12 automatic submerged arc welding trolley is a horizontal submerged arc welding equipment, which is widely used in submerged arc welding butt joint of flat plate and arc plate and horizontal submerged arc corner welding.

The trolley consists of a traveling car body, a welding gun clamping device, a submerged arc welding agent blanking device and a flux recovery device; The car body is driven by brushless motor and driven by chain. This trolley is small in size, light in weight, and very convenient to move and use. It can replace the welding work of most vehicle-type submerged arc welding equipment in the market, improve production efficiency and ensure welding quality. No submerged arc welding power supply is required, and the gas shielded welding power supply can be directly used for welding. Single gun or double gun can be used for welding, and ordinary 1.4-1.6 solid welding wire can be used. The welding gun should be clamped on the shaker with the gas shielded nozzle removed, and CO2 gas protection is not required during welding. Submerged arc welding flux protection is adopted, and the flux recovery device is provided, which saves the material cost. The trolley is equipped with a swinging device, which can be used for swinging submerged arc welding. It has the characteristics of high deposition speed, high welding speed and high production efficiency.

The main body of this welding machine is the same as THCD-9 all-position welding machine of our company. It can be used for vertical and horizontal corner welding or butt welding of workpieces in various positions. With the built-in high-performance permanent magnet and guide wheel, it can automatically track the welding path (such as the welding of plates, ribs, beams and other workpieces). Its structural features are: battery power supply, especially suitable for outdoor and welding occasions where it is inconvenient to provide trolley power; The trolley is light in weight, and the magnetic adsorption has the function of automatic clutch by lifting the handle, which is convenient for operators to work on site; The trolley has swinging function and is suitable for welding wide and thick welds; The trolley runs stably and reliably, and even operators without professional skills can get good welding results.

2. Features:

2.1. Clutch device is installed on the car body, which can manually move the car body quickly.

2.2. Digital display of all operation functions is convenient for adjusting various parameters.

2.3. The walking speed, swing speed, swing angle, left and right residence time, etc. are precisely controlled by the program.

2.4. The swinging device is controlled by the program, and the swinging belt has the functions of left stop and right stop to prevent the phenomenon of insufficient molten pool during swinging welding; At the same time, the weld center can be adjusted during welding to prevent partial welding.

2.5. Swing function always starts from the center and automatically returns to the center, which is convenient for adjustment.

2.6. Bring its own flux recovery device to reduce the workload of workers to add flux and save the cost of materials.

2.7. 1.4-1.6 ordinary solid-core welding wire is used as welding material, so there is no need to purchase another submerged arc welding material.

2.8. Ordinary 500A gas shielded welding power supply is used as welding power supply, and submerged arc welding power supply is not required; The welding torch is still a conventional CO2 welding torch, so there is no need to purchase another welding torch.

II. The applicable workpiece and shape:

1. Generally, it is used for submerged arc welding, submerged arc fillet welding, etc.

2. The walking width of the welding trolley should be greater than 400mm, and sufficient walking position should be reserved for the trolley during welding.

3. The gap between the weld base material should be consistent, and the backing weld should adopt a small gap, otherwise it will affect the welding effect;

4. The workpiece should be made of magnetic conductive material. If there is no magnetic conductivity, the track magnet can't be adsorbed on the workpiece, which will cause the unstable operation of the trolley.

5. It is suitable for solid welding wire with φ below Φ1.6mm.

6. Track should be installed when walking in horizontal butt welding, and guide wheel should be installed when it is used for fillet welding.

III. Design Standards:

Q/320114 DRDJ 010-2016 H Series Automatic Welding Machine

IV. Specifications and technical parameters:

1. power supply: nominal voltage of XC-24040-2 lithium battery pack is 24V

2. Walking speed: Vmax=930mm/min Vmin=35mm/min

3. Driving and tracking mode: 4-wheel drive with optional guide rail for copying walking.

4. Swing parameter: Swing angle 0 ~ 8, maximum swing speed (rotating speed of output shaft of oscillator): 5.4r/min.,Left and right residence time: 0 ~ 2.5s.

5. Welding torch adjustment: 40mm horizontally+30 mm vertically,The welding clamp rotates around the X axis (referring to the wheel movement direction of 45, the welding clamp rotates around the Y axis of 30)

6. Flux recovery method: compressed air vacuum recovery.

7. Flux hopper capacity: 3K,Adsorption force: 32kg

8. Dimensions: length× width× height 480×400×680mm.

V. Inspection and maintenance:

In order to use the automatic welding trolley safely and for a long time, the equipment should be maintained regularly.

1. Remove the splash from the control box panel and welding torch adjustment part: always clean the splash from the control box panel and welding torch adjustment part to prevent the circuit board from being damaged and the welding torch from being unable to be adjusted.

2. Removal of welding slag: Always remove welding slag and foreign matter from the guide wheel, driving wheel, track, magnet and slider.

3. Fasten the screws of the welding gun fixture and the guide wheel: if they are loose, they will cause unstable walking and poor welding.

4. Often check whether the plug, welding torch control line is damaged, whether the battery can charge and discharge normally.

5. Regularly check the running status of the traveling motor, swing motor, traveling mechanism, etc. to confirm whether there is abnormal fever or noise.